Autonomous production is now

From 1859, when Colonel Edwin Drake successfully drilled America’s first oil well in Pennsylvania and over the next several decades, the oil and gas business was primarily driven by manual labor.

This meant high vehicle mileage, and lost production time because pumpers and engineers were constantly needed on location, which resulted in operational inefficiencies and many safety issues. Until the introduction of automation technology into the oil and gas industry.

As automation technology has progressed, from cable tools to rotary drills; from car phones to palm-sized smart phones; from desktop computers for accounting to ubiquitous sensors sending big data through the cloud to smart devices; oilfield efficiency has continued to cut costs, save time, boost production and improve safety.

SCADA system beginnings can be traced back to the 1960s, but oil and gas adoption became widespread in the early 2000s. Those who have embraced SCADA, remote monitoring, remote control, and autonomy even on a small scale are already benefiting from reduced downtime through increased operational efficiency—which means more production, fewer costly repairs, and more importantly a much safer work environment with less windshield time.

Now, with oil and gas technology moving towards full autonomy—where artificial intelligence (AI) driven systems and machine learning through analytics relieves humans of more and more of the basic troubleshooting as well as operational and system adjustments—producers are able to make a profit at lower oil prices. Even when they factor in the cost of automation, it still only makes sense to keep growing production and increasing the bottom line while embracing these new technologies.

The autonomous future is now, with Emerson's DeltaV SaaS SCADA that operates exactly as described above, complete with AI and machine learning to give our customers and partners the advantage of autonomous operations - now.

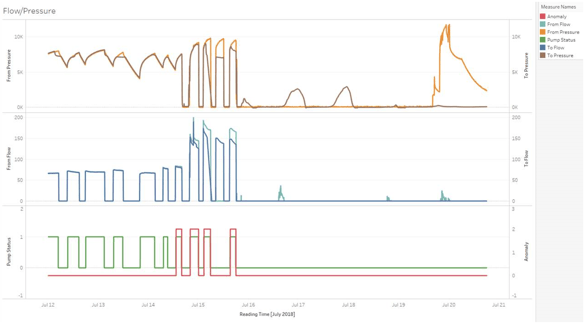

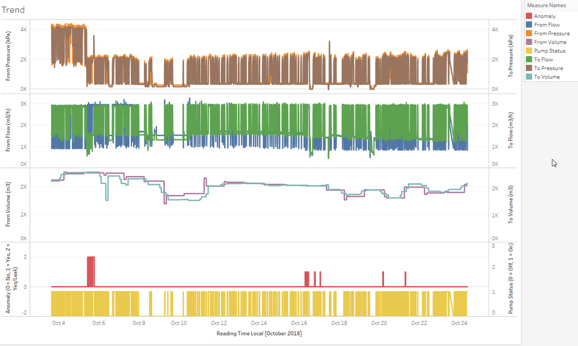

Hardware and sensors collect thousands of data points in the field, such as flow line pressures, flow rates, tank levels and more, at high-resolution intervals. This advantage changes everything for producers, granting them a full range of instant and actionable information to not only be aware of any issues, but to automatically fix the problems; sometimes before their even a problem at all.

During the process our cloud based solutions compare that information to its database, looking for statistically significant variations. It doesn’t flag every minor pressure change or flow rate change, small fluctuations are just a day in the life once it’s ‘learned’ the regular operational performance for a specific asset.

When the system does see a trend that has previously led to a failure, leak, gas lock, etc., it takes note and autonomously decides how to proceed (based on the settings and permissions you’ve granted).

When that system includes an adjustable hydraulic artificial lift system it can autonomously regulate pump speed, stroke length and frequency according to priorities given in a 15-point solution protocol. Our platform can tell within minutes if its solution it put into action worked, if it needs to try the next option, or if it should alert a field technician through an instant alarm cry-out.

This solves a huge percentage of common problems sooner than traditional methods could even detect or action on one. You can see how this cuts downtime and boosts production. Even when onsite visits are needed, and helps the technician decide on recommended parts and tools that are needed, reducing onsite decisions, and unnecessary trips back and forth to the site.

This involves human intervention only when a report is sent after the issue is solved or for major operational issues. Technicians are not driving needless and inefficient miles to check on a perfectly operating artificial lift system while a different location has major failures just up the road.

While our solutions combined with an adjustable hydraulic artificial lift system it currently handles some issues, it’s an important technological step towards allowing producers to move past tedious data tracking and evaluation. It lets the operations take care of things machines can’t do— like finding creative solutions to complex production issues and evaluating new drilling, acquisition and divestiture opportunities.

It’s no exaggeration to say that this future of autonomous technology in the oilfield isn’t the future anymore, it’s right here, right now.