Everything you ever wanted to know about cloud-native IIoT SaaS SCADA

Emerson's DeltaV SaaS SCADA offers digital technologies which can autonomously optimize your operations while maximizing the productivity of you and your employees by empowering them with just the right amount of accurate, analyzed data, at exactly the right time and place without causing you, or your operations to get overloaded with detail that you don’t need, or want to deal with; while still knowing it’s there and as easy to attain as clicking a button to get a specific report that will provide you with the answers you need from anywhere, at anytime.

DeltaV SaaS SCADA people are exceptionally committed to your success, driven by our customer first culture and foundational belief in supporting our customers and each other to deliver the most effective solutions that generate more production, profits and sustainability.

Emerson is where technology and engineering come together to create solutions for the benefit of our customers, driven without compromise for a world in action.

The Emerson approach enables you with clear visibility so you can SEE and identify issues, quickly DECIDE on the course of action, and ACT to close the loop by applying new set points to the process much faster than traditional manual analysis methods – this process could take weeks or months with traditional approaches – autonomous operations is achievable with the technologies that exist today, shortening this process to days, minutes, and even seconds.

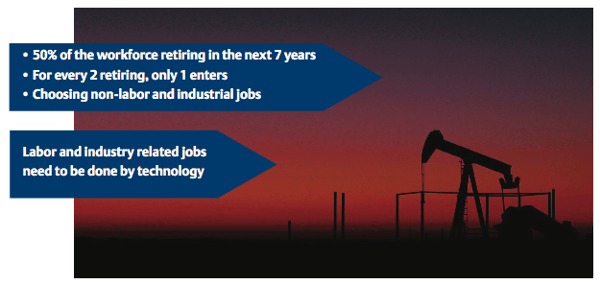

We see autonomous operations as a significant part of where industrial operations are quickly heading out of necessity. Lack of skilled labor in the workforce, an unbalanced amount of fast approaching retirements and negative industry based narratives can quickly deter potential newcomers to the industry or steer them into other directions in their career paths.

Autonomous operations is really about up skilling your people so they can focus on critical decision making activities and reduce the effort and budget needed to maintain and run the ongoing operation, all while setting it up for long-term, sustainable return.

Our goal with this white paper is to help you gain a stronger, more exhaustive understanding of how to strategically align with the right digital transformation plan in place, and how to get the most value from your investment while learning the ins and outs of everything cloud platform based to reach Top Quartile performance for not only short-term gains, but long-term sustainability and growth.

Highlights of this paper:

• How advanced data analytics can change your world (for the better)

- What makes an IIoT cloud different than on premise systems

- Mobility, freedom and flexibility

- Security is everything

- Implementation made easy and fast

• An introduction to the Journey to Autonomous

- What autonomous operations can really mean to you

How advanced data analytics can change your world (for the better)

When it comes to driving stronger business decisions and today’s need for speed to protect people, assets and the environment what every operation needs is to understand the mounds and mounds of endless data that intelligent devices can present.

This data is seemingly endless in what it’s able to inform you of, but often times can be daunting to try and sift through those piles of data to find the answer to a challenge you’re currently trying to solve. Much of the data is not always needed at that particular moment. You want and need ‘actionable data’ for data to make a positive impact to your decision making abilities and not be overwhelmed by ‘big data’ that can easily get out of control and end up eating your reaction time to a resolution.

An example of positive, clear, actionable data is when your tank is close to overflowing you don’t need to know that your compressor is operating just fine; you need to know - what you need to know, and you need to know that right this second without manually reading through tons and tons of charts, spreadsheets or worse yet manually compiled information.

The ability to simply hit a button and be presented with the exact report, or an alarm notice or other detailed data that is directly impacting your site or facility is key in generating the decision making data you need. Our cloud based platform delivers exactly that. If you decide from that one report you want even more layers of detail of course it’s all there and simple to access it. But, it’s not cluttering up your vision on the current issue you’re trying to resolve. It’s clear, impactful and insightful.

Many operations are not set up with in-house platforms that can deliver advanced data timely or effectively with a clear, concise dashboard of all those things you need to know right now, verses what are nice to haves and bigger picture data you need when planning the future of your operations to help you strategically align with what is best for the future.

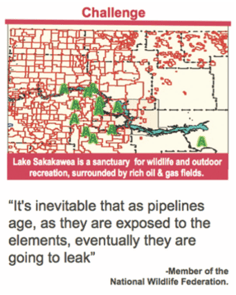

One example of how advanced analytics can provide actionable data that results in priceless value and is based on how analytics is used for saltwater disposal pipelines to provide leak detection near a popular regional recreation destination for fishing, camping, boating, hiking, and other outdoor water-based recreation in North Dakota. These oil production well site pipelines are shorter in length—less than three kilometers, or under two miles—but when they develop a leak, they can quickly do hundreds of thousands of dollars’ worth of damage, tarnish your brand reputation and harshly impact your local community safety of people and the environment.

Pipeline leaks rapidly lead to expensive repairs, remediation fees, fines and lost operational time with mandated shutdowns in operations until the problem has been investigated and fixed.

When using sensors like temperature, pressure and flow rates correctly placed in a pipeline segment and connecting those sensing inputs to a SCADA host that then provides accurate data to machine learning algorithms on the host, we can then detect anomalies and ultimately ‘see’ leaks by using these analytics to see beyond the data and information you may already have to create the knowledge and wisdom of high-risk events in production.

When using sensors like temperature, pressure and flow rates correctly placed in a pipeline segment and connecting those sensing inputs to a SCADA host that then provides accurate data to machine learning algorithms on the host, we can then detect anomalies and ultimately ‘see’ leaks by using these analytics to see beyond the data and information you may already have to create the knowledge and wisdom of high-risk events in production.

Lake Sakakawea is a popular regional recreation destination for fishing, camping, boating, hiking, and other outdoor water-based recreation in North Dakota. Exposing risks associated with saltwater pipeline leaks to any area can have devastating impacts, but especially when considering a cherished destination for people to enjoy the great outside with their families and friends.

Keeping all areas and people safe from a pipeline leak is of an utmost importance to protecting these facilities and keeping strength in your brand reputation. With the right data presented to you at the right time from the sensors telling of temperatures, flow rates and pressures combined with machine learning to understand what all that data coming through actually means to the end user (us, the humans) is what can make advanced analytics priceless to your organization and the communities you proudly serve and want to keep safe.

Having several oil and gas rich fields nearby Lake Sakakawea with aging pipelines surrounding these types of areas that are exposed to the elements with a strong potential that they will eventually leak is a perfect reason for utilizing technology that makes the world safer and better for us all.

DeltaV SaaS SCADA provides data reporting after it has ‘learned’ enough from your pipelines can actually identify anomalies in pipelines, not just leaks and can detect those leaks as small as 1% of total flow within 30 minutes while also detecting build up in flow, identify compressor problems and uncover meter errors, and maintenance needed on meters.

What makes an IIoT cloud different than on premise systems

Today, most people are taking advantage of the freedom and flexibility cloud computing offers us in our every day lives using cloud-based applications and different platforms for functions like email, banking, shopping, ordering food, getting a baby-sitter, having errands run, deliveries, making appointments, seeing who is on your doorstep, turning your lights on and so much more. The wide use of cloud computing in industrial businesses has only recently started to become more widely accepted and utilized with open arms.

We purposely built DeltaV SaaS SCADA from the ground up specifically for secure, operational gains for our customers, with actionable data presented the way you want it, and impressively detailed and vivid trending and reporting it presents to authorized users.

Industrial internet of things (IIoT) cloud based platforms are not all created equal, and certainly not the same as a traditional in-house or on-premise SCADA system; although every system has it’s place in the world, we would like to define the most significant differences here so it’s clear what a cloud platform can deliver verses a more traditional approach.

This includes walking you through all the details; and there is a long list of all those massively amped up levels of communications, networking and security that we’re happy to explain in an easy-to-understand language that you don’t have to have a Doctorate in technology to be able to easily comprehend the benefits to all those layers of techie talk.

Most people are now aware of the term “IoT” or “Internet of Things” and all the promises it brings with it to change the way we work in almost every industry. With real time visibility of operations and new ways to access expertise, there is a lot of opportunity. Despite the significant promise, the vast majority of companies do not yet have an in depth strategy.

A relatable example for many people is the IoT thermostat. One aspect of an IoT thermostat is the app in your phone that allows you to control it remotely. What is worth noting is there isn’t actually a connection directly from your smart phone to the thermostat. Instead, they’re both communicating to the internet, sending and receiving information in a safe and secure place on the cloud.

This is why that app allows you to control your thermostat from your house, from your work, or the coffee shop down the street. As long as you have internet, you’re connected. And that connection is simple – because we don’t need to worry about the nuances of making this specific thermostat talk to your particular phone, everything comes out of the box, knowing how to securely publish and subscribe to data in that common place.

This is why that app allows you to control your thermostat from your house, from your work, or the coffee shop down the street. As long as you have internet, you’re connected. And that connection is simple – because we don’t need to worry about the nuances of making this specific thermostat talk to your particular phone, everything comes out of the box, knowing how to securely publish and subscribe to data in that common place.

What’s more, the rest of your family can simply download that same app, and can be given access to that same thermostat with just a simple click to authorize them.

It’s easy to see how this type of concept could be extended into automation – it’s very powerful – the easy and seamless way that the devices connect to the cloud and share information is extremely robust. How does the approach taken by the IoT Thermostat apply to industrial operations for oil or gas production, water and wastewater management, gas distribution or even cold chain helping from farm-to-fork challenges?

To tie this back into the Industry’s we proudly serve, let’s start with what we should all be familiar with, which is the traditional Purdue model.

Traditionally, the SCADA network is isolated from the rest of the world for security purposes, and a SCADA system have been meticulously designed to poll all of the specific field devices for their latest state and telemetry through direct and dedicated connections. This approach has been followed for decades now, and for good reason! We know that field devices depend on proprietary protocols that often times are not secured so we need to keep those communications separate from the rest of the world.

What IIoT does is essentially flip all the SCADA principles on their head. Instead of having an isolated network from the rest of the world, all field devices are securely connected to the cloud. Instead of having a central system painstakingly designed to interact with each and every device on that network, the field devices themselves will simply publish data whenever their state changes. Instead of having mixed proprietary and legacy protocols for transmitting data, you have more expressive protocols that are based on open standards, created to be secure from the ground up.

What this all means is much like our thermostat example, these devices come essentially out of the box ready to be used in a highly secure and efficient way, without having to redesign security, communications and network topologies the way we’ve had to in the past supplying you with a much simpler architecture that is not proprietary to a specific vendor and doesn’t compromise on security.

IIoT also addresses some of the pains we have seen historically when using SCADA systems. When each field device is able to publish data when a change is detected, it means that we will have a much richer and accurate set of data than before, without any wasted bandwidth. Also, since we are leveraging the cloud we can count on its scalability to handle the larger volumes of data without impacting existing processes.

Leveraging the cloud is really the main point here. Data is no longer ‘trapped’ in an isolated network. Both SCADA users and non-SCADA users have easy access to the data that is being published by your assets without compromising on security. Because of the simplicity of IIoT architectures we can execute new deployments quicker and cheaper than ever before.

The cloud also allows companies to rely on software-as-a-service models where the vendor is accountable for keeping the system running 24/7 as well as publishing updates and enhancements to the platform without causing a disruption. This means that customers can focus on operating their business, while allowing a strong technology partner to handle all of the details of providing the software platform that they require to run that business. So now our customers can develop an in depth strategy around digital transformation, knowing that they can have someone on their side positioned to help them realize that strategy.

One of the most significant key takeaways is that starting with a well-composed strategy in place of where you want to go and how you want to leverage these technologies is key for successful implementations.

Even without a strategy, there are more and more devices being connected to the internet. In study after study, we see the numbers growing exponentially of assets being connected. The upside is we will be able to gain more visibility and control, the downside is that without a well thought out plan, we run the risk of having a multitude of disconnected, random systems that don’t really benefit you or your organizational goals.

What’s more is that you can get all of these significant gains of using a cloud based platform with major costs savings of a much lower capital investment compared to trying to manage the giant worry of security, the amount of IT people to maintain it, money and time spent on training your team, and of course the factor of endless amounts of hardware costs and needed support to keep it all up to date and functioning properly. Bottom line is that it may seem cheaper to do everything yourself but that is definitely not always the case with so many levels of hidden, unforeseen costs.

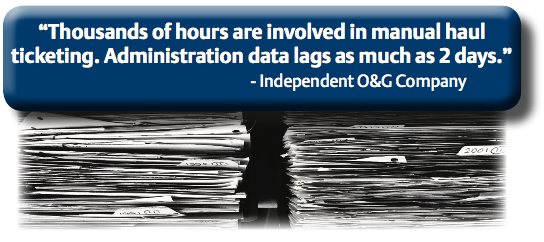

When it comes to making your data work harder for you we had a customer that used our tank solution to automate their haul tickets. In this simple application they estimated reducing there fiscal risk from $19.7MM per year on their oil hauls and eliminated $1.5MM/yr on water disposal cost overcharges.

Our Tank Monitoring and Control application automates the entire hauling process. It provides a secure user-friendly human machine interface (HMI) for the driver to log and report transfer events. Security is available to limit driver access and for tracking haul volumes.

When a haul is completed, DeltaV SaaS SCADA with Truck Ticket View creates an electronic haul ticket that includes driver, ID, haul volume, corrected haul volume, and hauled time and date. A ticket can be printed for the driver’s records. Then you have confirmation of each haul ticket by introducing an audit trail that record all pertinent data. Data can be uploaded to the companies SCADA system and to their production accounting system automatically minimizing manual data entry.

This resulted in one of our customers that was processing 3,000+ manual haul tickets per month. The ticket data often lagged behind by as much as 2 days, and required dozens of operators and several administrators to manage entry and correction of tickets. They also had to administer a seal program to avoid theft.

With DeltaV SaaS SCADA with Truck Ticket View all tickets are transmitted into the production accounting software within minutes – no manual entry is required. The customer was able to reduce manpower by 12,000 hrs per year (6 full time equivalents) for ticket entry, ticket correction and seal program administration.

Mobility, freedom and flexibility

Authorized users can enter, monitor and manage operational data from anywhere, at anytime with DeltaV SaaS SCADA Mobile. Gaining you not only operational safety for problems like an overflowing tank, but also increases your people’s safety by reducing trips to remote sites for no actual reason other than to simply ‘check’ on your assets and see if everything is in proper order.

Now authorized users can check their phone to see if the trip to the remote location is needed at all, or simply a waste of time that could be much better spent doing something else that focuses on your core business and drives stronger bottom line results.

Alarms are easy to set up and you can customize thresholds for them to go off and who they get sent to so you have total control over who knows what, when and why.

The key advantages having access to a mobile app are three-fold:

• First and foremost, your entire team probably already has smartphones; so you don’t need to make an investment into ‘new’ hardware or software technology; most individuals are pretty comfortable using smartphone apps on a daily basis in their personal and work lives.

• Secondly; a cloud SCADA mobile app acts as a SCADA system on the go with the ability to make operational data available immediately to all authorized users. Instantly your team can monitor, remotely control and enter data as needed to keep everyone up to speed and your automation strategy on the cutting-edge.

• Lastly, but certainly not least; Instant data access and alerts mean you no longer have employees making 2 hour round trips just to ‘check’ remote well pads. Their operational responsibilities are now at their fingertips.

The freedom that evergreen platform enhancements enable your people with is when any change, upgrade or update happens to the cloud platform and you don’t have to do a thing. Nothing. The updates simply happen without any data downtime, data loss or anyone even having to reboot.

The days of dreading an update because your system will be down for an undetermined amount of time as your IT personnel scramble hoping nothing horrible happens can officially be over.

Now your IT people can focus on efficiencies within other parts of your core business and not be trying to balance a platform that in all reality probably isn’t their specialized or first choice of focused areas. Now you’ll always have the most up to date software available without all the operational costs associated with things like hardware, time and unforeseen challenges that can quickly grow into full-blown data catastrophes.

Other freedoms that cloud SCADA technology immediately grants you are accessibility to trending, reporting, live data screens, device control, alarm analysis, production records and 3rd party data exchanges. It comes pre-designed to offer a variety of user-friendly interfaces and to streamline data processing.

Delivered as a service a cloud platform has all of the features any industrial organization needs and is inclusive of ease of deployment, server redundancy, historian management and much more; essentially everything you need to make the best use of your production data from sensors and automation equipment for a fast return and continuous capital efficiency.

This also drives an infinite amount of flexibility that is completely based on your growth and needs. Cloud SCADA enables you to quickly and easily scale up (or down) based on your exact operational transitions without worrying about hiring (or laying off) any workers to help support your internal change.

Quality cloud-native IIoT platforms like DeltaV SaaS SCADA are fully supported by exceptional service with ‘always on’ help, 24/7/365 support via a call, text or email to be sure if your people have any questions at all they have someone to contact that will either have the answer, or get it for them in a timely manner. We also offer complete training either on a call, in person (when available) and several training videos for new users so that everyone in your organization understands and is able to easily use, configure and best-use applications to get the data they need for your operations success.

Security is everything

Based on data security concerns and already spent high levels of budget previously invested through the years into on-prem SCADA platforms, many industrial verticals have (in the past) had a difficult time trying to make sense of layering on another platform to what they already have set in place, or scrapping it all together for a cloud based version, until now.

Emerson offers a wide variety of secure communication options with regional cellular and global satellite providers. The connections we provide are encrypted and secured from the communication device back to the cloud-native IIoT infrastructure through dedicated Access Point Names (APNs) and Virtual Private Network (VPNs) with our telecom partners.

Full data backups occur nightly, and storage amounts are not limited, nor quota driven with zero limitations on content or data fields with ‘always-on’ continuous security monitoring platform performance.

Full data backups occur nightly, and storage amounts are not limited, nor quota driven with zero limitations on content or data fields with ‘always-on’ continuous security monitoring platform performance.

Next up is of course the very common question of “who owns our data we put into DeltaV SaaS SCADA?” A perfectly great question because all clouds are not created equal, or secure for that matter. But, for our SaaS SCADA platform it’s an extremely clear-cut answer; It’s YOUR data, and you own it all.

The other piece to this is that anytime you decide you want to download or export your data (in almost any format) it’s easily accessible to do just that. We promise we’ll never hold your data hostage, and you will always be enabled to export your data.

When it comes to working with your current in-house SCADA system or most third party applications we realized long ago that this was indeed a top priority since many operations have spent large amounts of budget into creating and maintaining their own systems and are not willing to simply step away from it all; the great news here is that you don’t need to. You may decide later on you want to, but that’s entirely up to you, and when you’re ready.

Implementation made easy and fast

You may already have some sensors or other hardware devices at site, and we can work with almost any that you may have currently in place. Emerson also has everything you may need and is quick at getting it professionally installed for you. Once the hardware is in place it’s easy to get started taking advantage our cloud-based platform.

Quickly gain operational data from remote locations and get your automation up and running in weeks, not months, or years. Our best-practice automation solutions are ready to install now, gaining you the data needed to make better business decisions. Easily explore automation options, and then quickly gain the ability to have them in working order and take advantage of all the benefits of our cloud platform.

Our people are exceptionally committed to your success, driven by our customer first culture and foundational belief in supporting our customers and each other to deliver the most effective solutions that generate more production, profits and sustainability. DeltaV SaaS SCADA brings you technology backed by services from every angle.

Your ability to operate successfully in any market conditions and your overall satisfaction isn’t taken lightly by our team that is designed to effectively manage your service requirements to new levels of safety, profits and sustainability. We have Project Experts, Alarm Experts and Support 24/7 support available.

There are several points to ponder on why you would want to make a switch to cloud SCADA, but one often overlooked situation that we often encounter to organizations wanting to keep both to keep their current on-premise system and to have the redundancy and ability to utilize all the benefits of cloud SCADA in addition to their current system. We have the technology and the specialists to make sure your data transfers seamlessly.

What autonomous operations can really mean to you

It’s no secret that up to 50% of the energy supply workforce will be retiring in the next 7 years. For ever two retiring, only one enters. Autonomous production operations is a vision for the future of energy production operations, but more so, a goal for the safety of our future energy supply.

For many years, the oil & gas industry has questioned whether there are simply enough schools to train the skilled labor required for the industry in the future and have talked about a shortage of skilled labor at some point in the future, especially with pending mass retirements. Combine this with the challenges that industry volatility has had on attracting skilled labor wanting to join the industry and have a long-term view with respect to a career in such a volatile industry.

In addition, we add the recent narrative around climate change, where we could see generations of people who choose not to join this industry as a result of the negative perception the industry has in the world. These are 3 major issues impacting todays and the futures labor forces for the oil and gas industry that can jeopardize the ability to meet the world’s future energy demands.

Emerson fully supports the oil & gas industry and is committed to the journey to autonomous production operations because the ability to supply the world’s energy demands may be contingent on delivering full or near full autonomous production operations due to lack of people willing and capable to work in the industry at some point in the future.

Despite the fact that our “why” is centered around the future supply of the world’s energy demands, it just so happens that all the same capabilities that we are building are required and relevant in a downturn like we are experiencing now.

Lowest cost and safest producer’s win and optimizing the production of existing assets when CapEx is scarce for new drill production are the key driver’s today and all the elements we build on the journey to autonomous are relevant now so this isn’t just about the future.

Driven to innovate the direction of the oil and gas industry to new heights for every operations need for stronger, long term returns. We’ve developed advanced analytics, artificial intelligence and machine learning that are quickly paving the way to autonomous oil and gas production operations.

Starting the journey to autonomous operations begins with your digital transformation strategy in place. From there it’s all about having the scalability for easy growth and flexibility to be able to add technology and gain more and more abilities and control from anywhere, at anytime to increase your safety and improve your focus on your core business.

Each step is really about implementing your carefully designed strategy with the largest amount of ease that will drive the biggest gains for your operation; since no two operations are the same you have to do what makes the most sense for you, of course we’re happy to help you figure out that end of it – what’s going to help you today and tomorrow; all based on what your goals really look like – and we know those can greatly vary!

Business have certainly been through several ups and downs through the years – and I think we all learned a great deal going through it, especially the last 5 years. But it doesn’t mean we can’t prepare our industry better for the next round of what the world dishes out....whether that is good or bad; and ultimately to make sure our kids, and their kids are on a better path of sustainability for oil and gas production.

We recognize that, just like any other significant change, the journey to autonomous isn’t completed in one step but with a stepwise approach over time. We’re well on our way to bringing autonomous production operations to life, although we have a ways to go with some of the more final pieces, we’ve definitely made strong strides the past year or so in that direction.

Emerson helps our partners adopt best in class behaviors and technologies, which can help you achieve top quartile performance. We do that through strategic application of our digital ecosystem. No matter where you are on your journey, whether you are just beginning or you are ready to take the leap to autonomous operations, we can help you apply our technologies to add significant value to your operation every step of the way, from the initial project through change management and adoption. We have the tools, industry expertise, and services to help you achieve your business objectives.

Zedi is Now Emerson's DeltaV SaaS SCADA